MODEX C-Suite Interview with Harold Vanasse: The perfect blend of automation and sustainability

MODEX 2024 once again proved just how vibrant, innovative and dynamic the full spectrum supply chain really is

Harold Vanasse, Global Sr Director of Marketing, Motive Power Global, EnerSys

Harold Vanasse, Sr Director of Marketing, Motive Power Global, EnerSys

MMH: What is your number one takeaway from MODEX 2024?

Vanasse: The industry is alive and well. It's not a sleepy little backwater industry. The record attendance for MODEX is rivaling the ProMat show, but more importantly, all the automation and technology was there on display and being demonstrated by more than 1,000 exhibitors. This is a very busy, advanced, non-stagnant industry where a lot of innovation is happening. For example, the amount of automation that was being presented at the show—and technology behind it—were amazing.

MMH: What are the three key market trends from your perspective?

Vanasse: Automation, electrification and sustainability. There was a lot of automation on display at MODEX. Sustainability is a message you see everybody talking about and rightly so, being that the majority of Fortune 1000 companies have established their own sustainability goals. And as the industry shifts from Class 4 and 5 lift trucks and over to Class 1 vehicles, EnerSys can not only help meet sustainability goals from carbon footprint reduction, water savings to clean air regulations, but these vehicles are also more affordable and reliable.

MMH: How is EnerSys responding to these market trends?

Vanasse: Being in the battery and charger world (the “power” world) and being able to absolutely contribute to these trends is really cool. It’s not this old school industrial place and the industry setting that it was even 20 years ago. It's more like, "Wait a minute, we're in the cool kids’ section of the trade shows now." If we look at automation, we showed a functioning wireless charger, charging an AGV with our lithium battery, and we’re taking orders now for those products. Wireless charging provides true automation when you have an AGV, so companies aren’t relying on a human to plug in or maintain “hot shoes” in an automated setting. That always garners a lot of interest. Finally, we offer a complete line of maintenance-free batteries requiring no watering, changing or equalization. They support flexible workflows with opportunity charging and offer time-tested durability and optimal performance.

Article Topics

EnerSys News & Resources

MODEX C-Suite Interview with Harold Vanasse: The perfect blend of automation and sustainability EnerSys showcases IP54-rated charger EnerSys honors Breast Cancer Awareness month with battery donation to ProLift Toyota Material Handling Enersys integrates its TPPL technology with Yale Power Key and Hyster Power Cellect EnerSys supports 2023 National Forklift Safety Day EnerSys celebrates opening of expanded Richmond, Kentucky DC EnerSys launches wireless charger More EnerSysLatest in Materials Handling

Vehicle-mounted computers: Beyond rugged New packaging idea for the cold chain Autonomous mobile robots (AMRs) offer modern solution to challenges of traditional farming Hyster-Yale Group provides students with real-world AI experience in 2024 Kellogg Design Challenge KION Group’s board extends CEO Rob Smith’s contract by five years UniCarriers Forklift joins Quality Equipment in opening celebration of new location Largest Automate on record opens in Chicago on Monday May 6th More Materials HandlingSubscribe to Materials Handling Magazine

Not a subscriber? Sign up today!

Subscribe today. It's FREE.

Find out what the world's most innovative companies are doing to improve productivity in their plants and distribution centers.

Start your FREE subscription today.

Find out what the world's most innovative companies are doing to improve productivity in their plants and distribution centers.

Start your FREE subscription today.

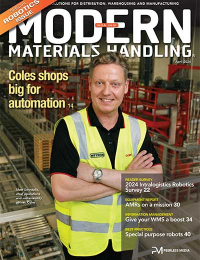

April 2024 Modern Materials Handling

See inside the highly automated Coles grocery distribution center.

Latest Resources

Materials Handling Robotics: The new world of heterogeneous robotic integration

In this Special Digital Edition, the editorial staff of Modern curates the best robotics coverage over the past year to help track the evolution of this piping hot market.

Case study: Optimizing warehouse space, performance and sustainability

Optimize Parcel Packing to Reduce Costs

More resources