The (Not So) Secret Weapons: How Key Cabinets and Asset Management Lockers Are Changing Supply Chain Operations

Solutions that can accomplish both represent crucial infrastructure that can be foundational to overall company growth and success. Key and asset management are among the technologies within that realm.

If warehouse operations are to evolve to meet increased economic demands, then the technology that powers them must advance as well. Those developments not only need to promote overall efficiency, but also ensure workplace safety. Operations and security managers need to continually evaluate their current solutions while collaboratively pursuing modern technology that can satisfy their established initiatives. Solutions that can accomplish both represent crucial infrastructure that can be foundational to overall company growth and success. Key and asset management are among the technologies within that realm.

Supply chain operations start with warehouse employers and their work starts with the tools they need. Shared assets like scanners, radios, and tablets are vital to overall operations and as such, how companies manage them directly impacts efficiency. Asset management lockers can store all shared assets in a central location, which reduces the possibility of them being kept in unsecure areas. These lockers can be equipped with charging capabilities to make sure assets are ready for use when needed, and programmed to release the most fully charged asset every time. The lockers can also be integrated with monitoring software, which allows administrators to see who checked out which asset and when. Having that clear audit visibility, including with curfew alerts that notify administrators when an asset hasn’t been returned, means lost assets can be identified faster, which reduces the amount of time looking for them. Lockers can also feature fault logging, which encourages users to identify when something is wrong with the device so it will not be checked out until that fault has been fixed. Collectively, these features create a system that extends the life of shared assets, which can save companies from unnecessary replacement costs. Given how expensive many of these shared assets are becoming, those costs can be significant over time and represent a clear example of a return on investment for this technology.

Like asset management lockers, electronic key cabinets are a central source for storing sensitive keys, which are in many cases the foundation of security in warehouses and distribution centers. Although key cabinets have been on the market for years, many companies are still operating in antiquated systems of logging and storing their keys, including through pegboards and manual logbooks. These faulty systems are susceptible to keys being lost, as they require accountability from multiple parties and tedious management for whoever is checking them out. Lost keys can obviously have drastic effects on operations, including with fleet management and overall security, which further enhances the need to have visibility on their usage.

Key cabinets can be programmed in a similar way to asset management lockers. Employees can access the cabinet through a variety of credentials including pin code, fingerprint, and security badge. Administrators can remote designate access to keys, which ensures that employees only have access to the keys they need for their job. This is especially useful for admins who need to manage multiple locations. Keys can be RFID-tagged and assigned a curfew, which, as noted above, helps alert administrators when a key may be missing and who had it last. Also like the lockers, key cabinets can be programmed with fault logging for fleet management. If an employee comes back with a vehicle that needs service or has a common fault like a flat tire or an oil change, the employee can note that in the system, which will remove that vehicle from circulation. This can eliminate the possibility of an employee unknowingly signing out a vehicle, including forklifts, that may be not working properly. Again, like the lockers, key cabinets can help save companies money by extending the life of vehicles and avoiding the need to re-key a facility if a sensitive key is lost.

Perhaps the greatest returns on investment that both lockers and cabinets provide is in time saved and peace of mind. Knowing where every key and shared asset is at all times is critical information that administrators can leverage to shift and direct resources to meet company goals. Downtime spent looking for lost items can instead be utilized toward increasing productivity, which can ultimately improve a company’s bottom line. As such, its incumbent upon organizations within logistics to evaluate their warehouse operations at the most basic level with key cabinets and asset management lockers. The impact both solutions can have is multi-faceted, both in day-to-day operations and long-term efficiency goals. Organizations that prioritize them take an important step in gaining an advantage over their competition that operate with outdated technology.

Learn more at the Traka Americas web page.

Article Topics

Traka News & Resources

The (Not So) Secret Weapons: How Key Cabinets and Asset Management Lockers Are Changing Supply Chain Operations Traka exhibits modular lockers The Power of Intelligent Locker Solutions and Electronic Key Cabinets International Retailer Optimizes Efficiency Through Asset Lockers Data Capture: Bar coding’s new friends Traka launches intelligent key cabinetsLatest in Materials Handling

Vehicle-mounted computers: Beyond rugged New packaging idea for the cold chain Autonomous mobile robots (AMRs) offer modern solution to challenges of traditional farming Hyster-Yale Group provides students with real-world AI experience in 2024 Kellogg Design Challenge KION Group’s board extends CEO Rob Smith’s contract by five years UniCarriers Forklift joins Quality Equipment in opening celebration of new location Largest Automate on record opens in Chicago on Monday May 6th More Materials HandlingSubscribe to Materials Handling Magazine

Find out what the world's most innovative companies are doing to improve productivity in their plants and distribution centers.

Start your FREE subscription today.

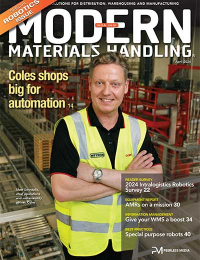

April 2024 Modern Materials Handling

Latest Resources